3 Ways To Reduce Part & Design Duplication & Reduce Material Spend with Aras & ShapeSpace

Many manufacturing operations maintain, make and purchase a huge number of similar and identical parts when in many cases a common part could have been specified. Engineers have often faced difficulty in identifying suitable carry-over or standard parts to use in new designs. It has been easier to create a new part than try to track down an existing one.The result, is an accumulation of similar and identical parts that do essentially the same job across different products. This costs businesses millions. More parts mean more tooling, reduced manufacturing economies of scale and higher inventories.

This begs the obvious question, if the costs of part proliferation and poor design reuse are so high, why do companies continue to struggle to develop effective strategies to deal with the issue effectively?

The Sources Of The Problem

First of all identifying and eliminating duplicate and near-duplicate parts ‘after the fact’ has not been easy. Until now, only the human eye has been able to discern (imperfectly) whether two part designs were actually the same. Faced with the overwhelming task of comparing designs across potentially thousands or even tens of thousands of items, companies have not surprisingly struggled to make progress. Secondly, companies struggle to develop effective approaches to help engineers find common and standard parts on future products because finding those parts relies on them having been classified properly in the past which either was not done or was done imperfectly. It’s a catch 22.

1. Install The Aras Shapespace 3D Search App

The Aras Shapespace 3D Search App can be installed on the server alongside Aras and is integrated with Aras. Every time a CAD model is saved into Aras, its shape is analysed using an advanced algorithm which generates a unique ‘geometric signature’ for that item. By comparing these signatures across potentially thousands of models, items of a particular desired shape can instantly found. This allows users to search for and find groups of similar or duplicate items already stored in the database. Engineers can then quickly identify duplicate or near duplicate designs contained in Aras, group them together and add them directly to an Aras engineering change request. A closed loop workflow driven process is then triggered via which the wider organisation is able to investigate the viability of replacing these duplicate items with a common part thus saving money.

2. Install The Aras Shapespace

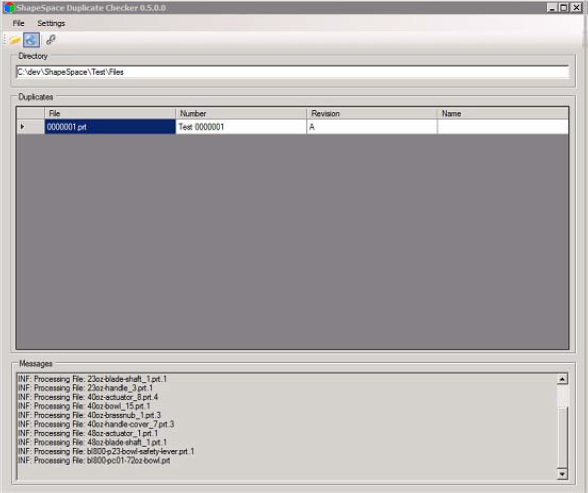

CAD Cache Monitoring Tool The CAD Cache Monitoring Tool stops duplicate CAD designs being saved into Aras. It monitors the local Aras working directory or CAD cache on the user’s PC (where work in progress CAD files, due to be saved into Aras, are stored). The tool indexes this folder by shape and also interrogates the shape index of files already stored in Aras. It compares the shape index of files in this local directory with the shape index of files already in Aras. When it finds that new local files are duplicates of files already in the Aras vault, it warns the user and reports the CAD item number associated with the file already stored in Aras. The user can then take the necessary actions to avoid a duplicate being saved to Aras.

ShapeSpace Part Browser Allows Duplicate or Similar CAD Models to be Browsed by Shape

3. Install The CAD Library Cleansing Tool

One of the main reasons for adopting PLM in the first place is, of course, to bring some order over product data. However, where there is a lot of valuable but badly organised CAD data to be migrated, this can pose some challenges. A common problem is that CAD archives contain many duplicate CAD files. The last thing companies need is duplicate parts cluttering up the new system. But how do you identify them efficiently, decide which one is the master and which ones should be eliminated? The answer, using traditional approaches, is not easily. As a result organisations spend hundreds of man-hours manually examining vast quantities of data before it can be migrated. The CAD Library Cleansing Tool can be used to quickly scan shared folders and archives on the OS by shape. The tool quickly identifies, groups & reports duplicate CAD files for the user who can then take the necessary actions to avoid a duplicate being migrated into Aras.

Duplicate Item Report & Dashboard In Aras

The CAD Cache Monitoring Tool monitoring the local Aras CAD cache for duplicates

For a closer look at ShapeSpace in Aras - Watch The Demo.

Tell us a little about yourself and we will tell you a lot more about ShapeSpace